Material Balance pabrik kelapa sawit 30 Ton [PDF Document]

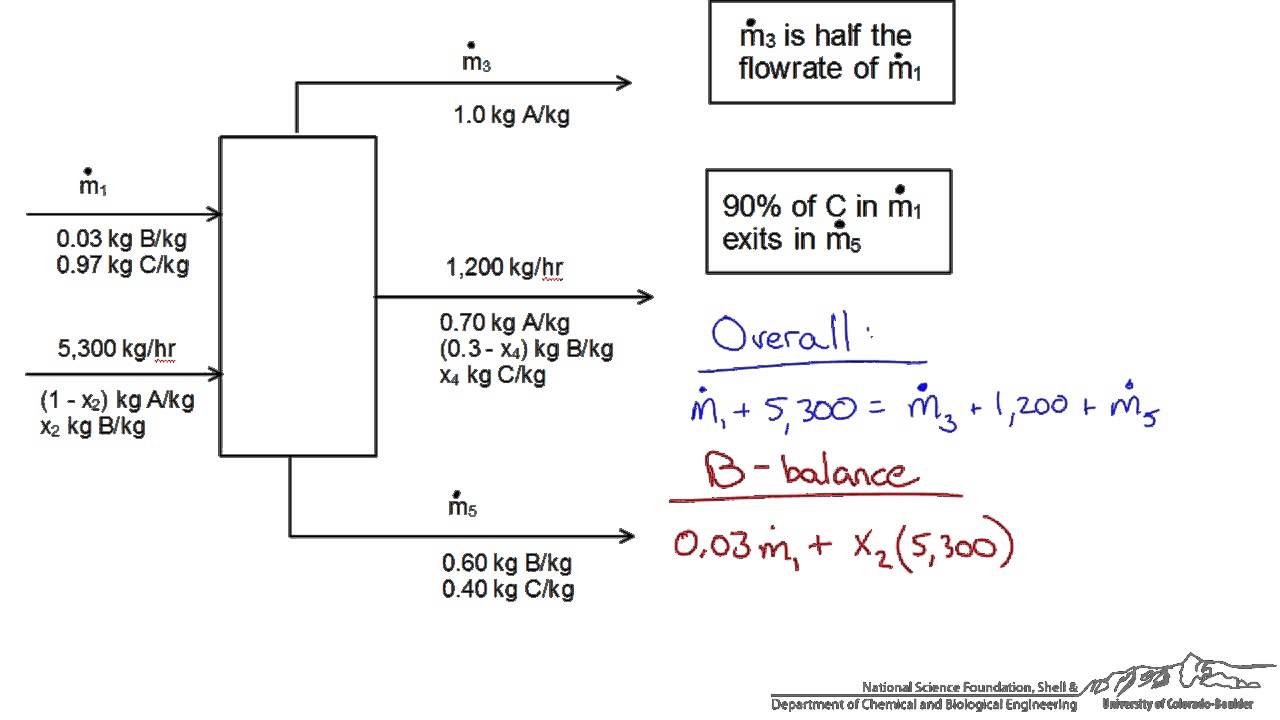

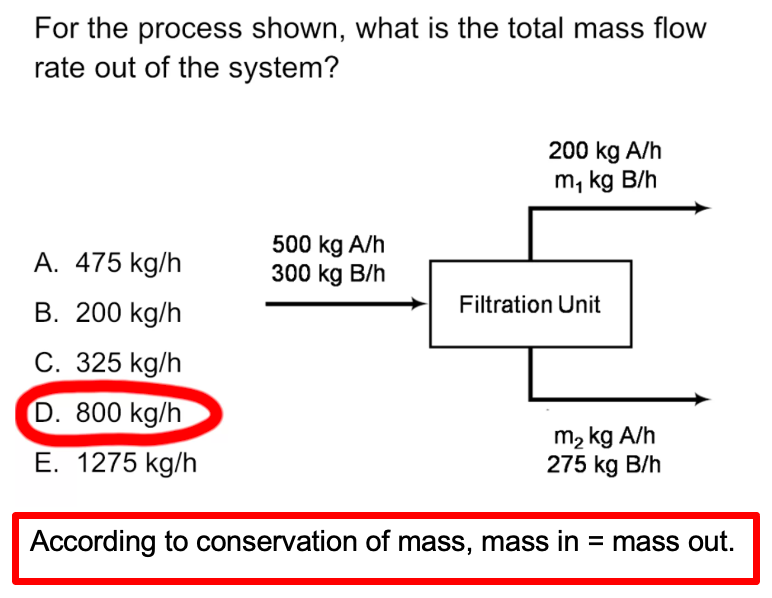

terms will become zero, and the balance equation for steady-state physical process will be simply reduced to: Input = Output 4.3. Balances on Single and Multiple Physical Systems 4.3.1. Procedure for Material Balance Calculations In material balance problems, you will usually be given a description of a process, the values

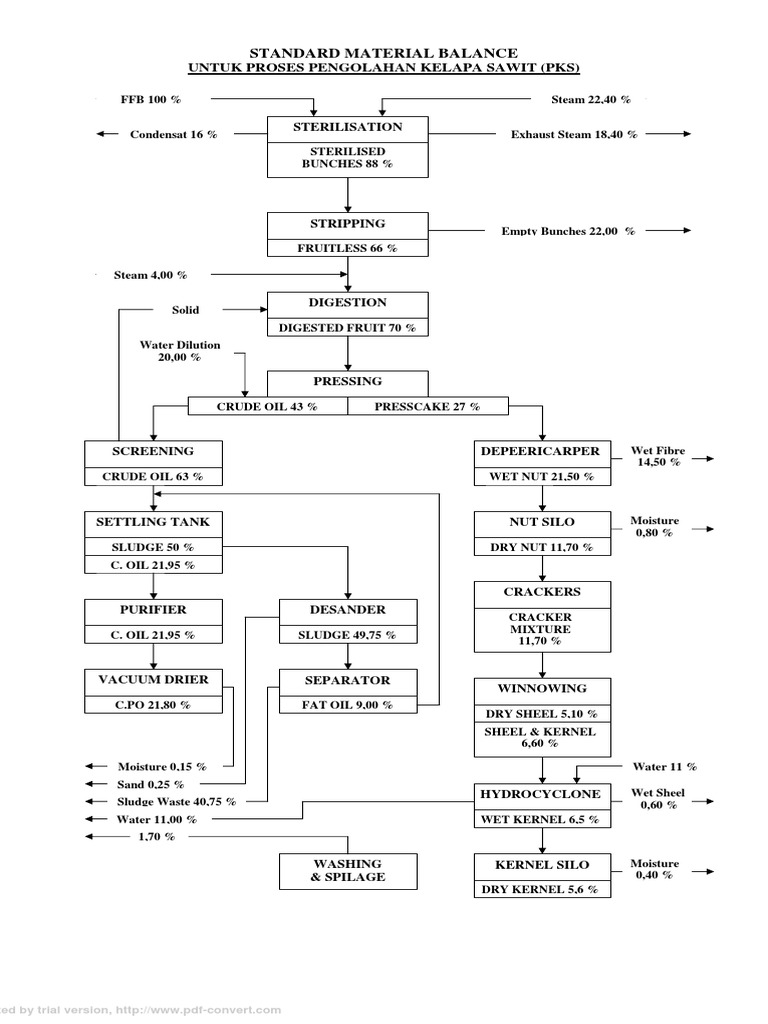

Standar Kontrol Pengolahan serta Material Mass Balance di Pabrik Minyak Kelapa Sawit kualitas

4.4 The General Balance Equation 150 4.5 Material Balances on Simple Non-Reactive Systems 151 4.6 Strategy for Making Material Balance Calculations 154 4.6.1 Guidelines for Setting up a Materials Balance 155 4.6.2 Guidelines for Resolving a Set of Equations 156 4.6.3 Objective a Materias of l Balance 157

Material Balance Model In Environmental Economics Common Good Matrix Economy For The Common

The document summarizes the standard material balance for a palm oil processing plant. It shows the inputs and outputs at each stage of processing fresh fruit bunches into crude palm oil and other byproducts like palm kernel, fiber, and empty fruit bunches. Key stages shown include sterilization, stripping, digestion, pressing, screening, settling, purification, and drying to produce crude.

Performing a Material Balance on a Single Unit YouTube

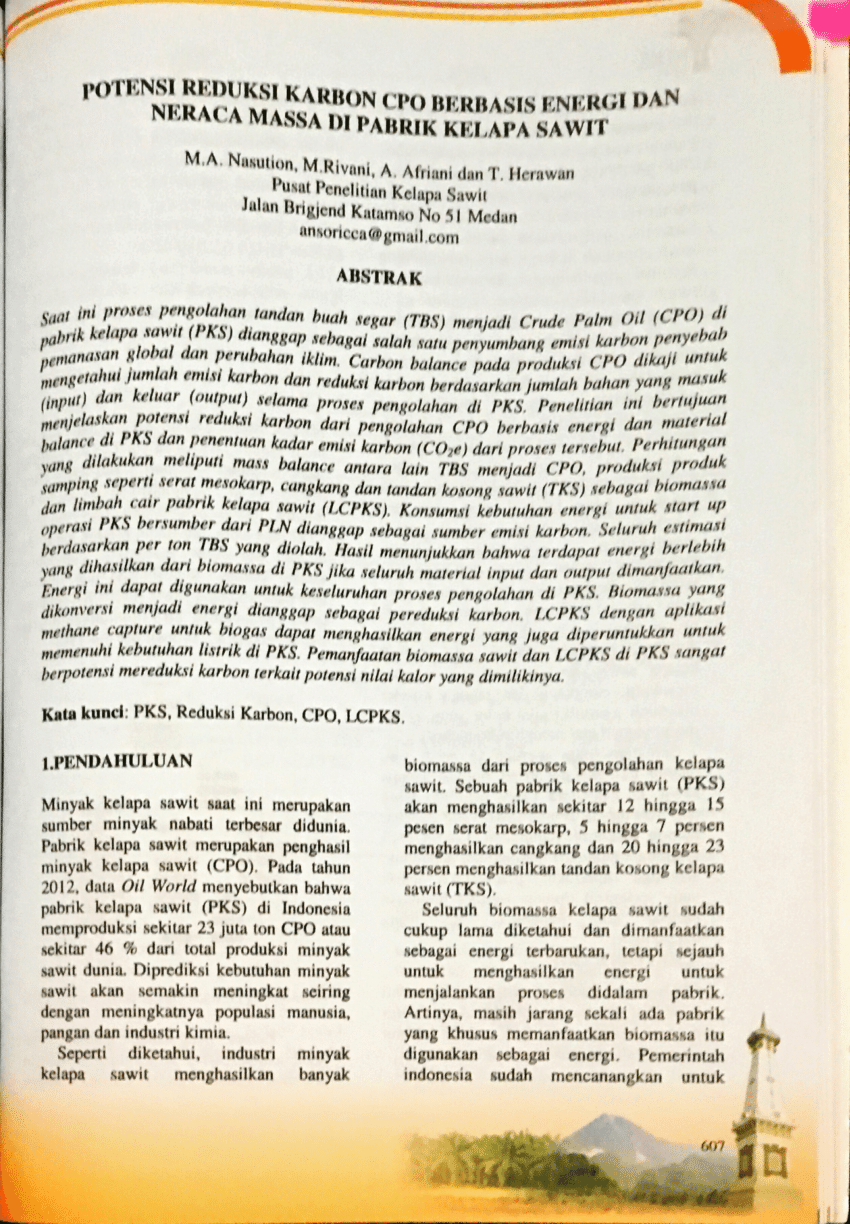

Figure 1 shows the typically mass balance in crude palm oil extraction industries. As shown in Figure 1, crude palm oil (CPO) is the main product of oil palm extraction industries, with every ton.

How to Perform Material Balances YouTube

The combination of material balance and exergy analysis is the next logical step to accounting wastes and emissions since exergy gives a quantitative and qualitative measure of material potential usefulness. References. Ayres RU, Ayres LW (1998) Accounting for resources 1: economy-wide applications of mass-balance principles to materials and.

(PDF) Potensi Reduksi Karbon CPO Berbasis Energi Dan Material Balance Di Pabrik Kelapa Sawit

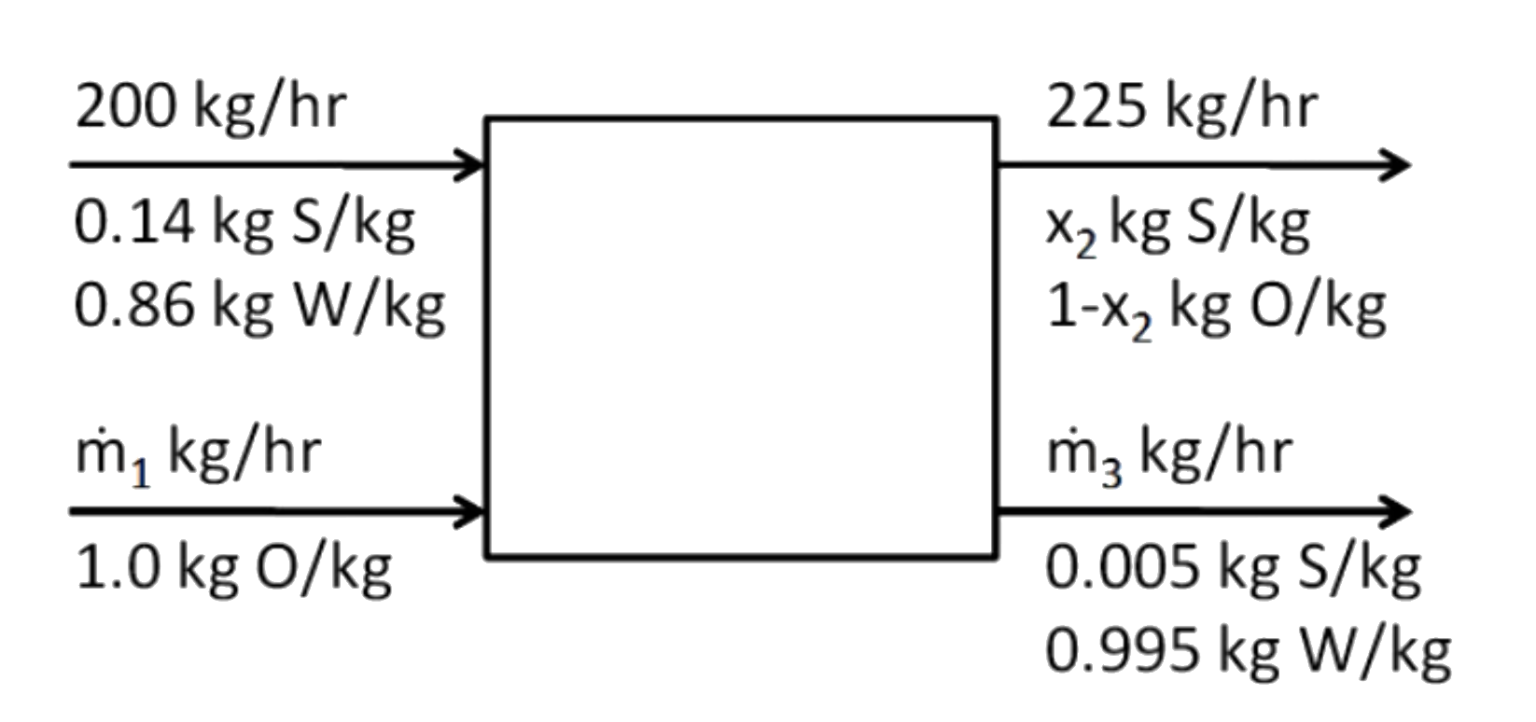

Material Balance Equation. As stated previously the material balances obey the law of conversation of mass, thus mass in is equal to mass out. The equation that needs to be remembered by every chemical engineer at all levels is: Accumulation = (Mass in - Mass out) + Generation - Consumption. Accumulation - The change in quantities of.

Palm Oil Mill Process Flow Diagram

What is a system? A system is specific part of a process specifically chosen by the process engineer to carry out a detailed analysis, in this case, a material balance analysis (Fig. 7.1). The dotted lines in Fig. 7.1 show the different possibilities for choosing a system for analysis. As we will explain later, in order to analyze the whole process, it is advisable to analyze it unit by unit.

materialbalancessummary LearnChemE

Uji Material Balance Pada Proses Produksi Pengolahan Tandan Buah Segar Plasma. diolah Inti hasil produksi = 4,58 % dari TBS diolah Losses Perbandingan rendemen minyak dan inti sawit dari hasil uji material balance dengan hasil produksi sesungguhnya di pabrik PTPN VII Suni pada tanggal 04 April 2020 adalah sebagai berikut : Tabel 2.

Material Balance Di Pabrik Kelapa Sawit Itu Mudah Dipahami !!! YouTube

Mahidin A. Taleb. Palm oil is one of the major agro industries in Aceh province. There are 25 crude palm oil (CPO) Mills in Aceh located in 8 districts with 551.12 tons/hour total capacity. The.

Standard Material Balance PDF PDF

254628708-Material-Balance-pabrik-kelapa-sawit-30-Ton.pdf - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document outlines the material balance of a palm oil mill processing fresh fruit bunches (FFB). It shows that 7.5 tons of total oil was produced from 30 tons of FFB, with a total oil recovery of 95.9%. 1.51 tons of total kernel wet was produced, with 1..

materialbalancesexampleproblems LearnChemE

The material balance method is a powerful technique in determining the important properties of a petroleum reservoir, including the estimates of original oil in place and gas initially in place, size of gas cap, and the strength of aquifer influx. It also provides an insight into the drive mechanisms at work, such as solution gas, water influx.

Berbagi Ilmu OER di Pabrik Sawit Majalah Sawit Indonesia Online

2.2 Material Balance Pengolahan Kelapa Sawit. material balance dari proses pengolahan untuk mengetahui banyaknya produk-produk yang dihasilkan dari setiap proses pengolahan. Perhitungan material balance dilakukan dengan cara membandingkan jumlah tiap-tiap produk yang dihasilkan dengan jumlah kelapa sawit yang diproses.

Komponen sketchup kelapa sawit legsmetrics

Dalam upaya meningkatkan dan menstabilkan hasil produksi atau rendemen Pabrik Kelapa Sawit (PKS) PT. Perkebunan Nusantara VII Unit Usaha Sungai Niru (PTPN VII UU SUNI) dibutuhkan terlebih dahulu. Material balance adalah perhitungan aliran material dalam suatu sistem. Dalam perhitungan material balance diklasifikasikan menjadi : 1. Proses.

Material balance in the process of separation and milling. Download Scientific Diagram

The Material Balance, as for the Mass Balance principle, is a consideration of the input, output and distribution (of materials, energy and/or substances) between streams in a process or stage. The Material Balance, on its semantic model, deals with material and/or energy quantities as they pass through processing operations.According to this principle, the balances are statements on the.

KONSULTAN DAN KONTRAKTOR PABRIK KELAPA SAWIT Kontraktor & Konsultan Pabrik Kelapa Sawit ( PKS )

From mass balance, the production of 1 ton of crude palm oil generates 1.41 tons of empty fruit bunch, 0.93 ton of fibers and 0.34 ton of shells as solid waste (Kramanandita et al., 2014). About.

PPT Material Balances PowerPoint Presentation, free download ID1119594

Material Balance pabrik kelapa sawit 30 Ton - Free download as Excel Spreadsheet (.xls), PDF File (.pdf), Text File (.txt) or read online for free. The document summarizes material balances for a palm oil mill processing 30 tons of fresh fruit bunches. It details the mass balances and efficiency calculations for oil and kernel recovery from the milling process.