Coal Surface Mining Materials101

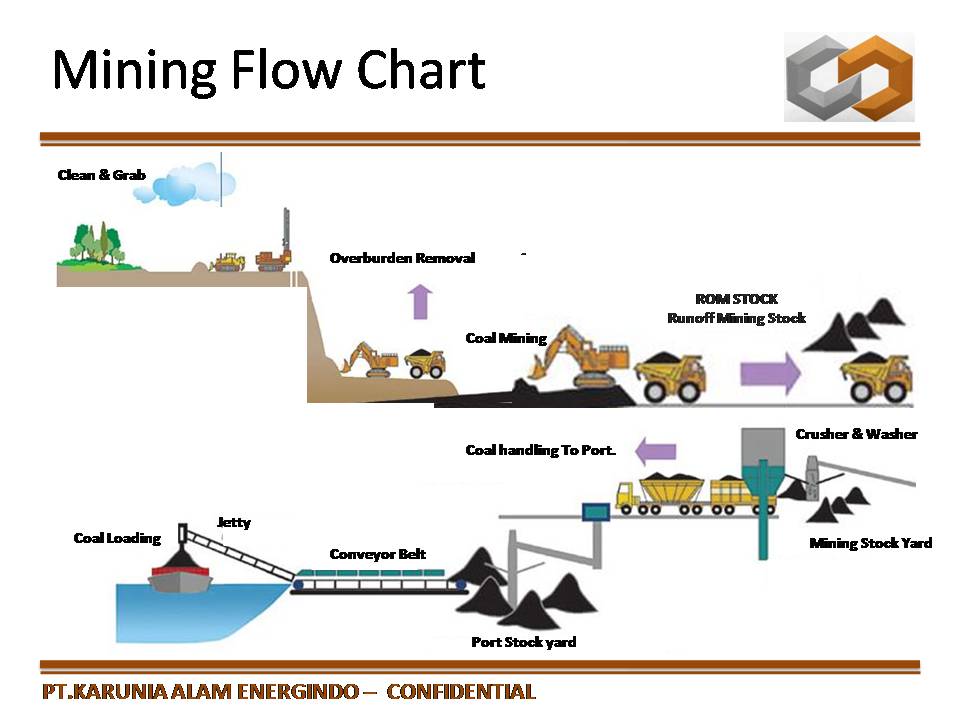

The overall coal mining process consists of several sequential stages: (1) exploration of a potentially economic coal seam to assess minable reserves, environmental issues, marketable reserves, potential markets, and permitting risks; (2) analysis and selection of a mining plan; (3) securing the markets; (4) developing the mine; (5) extracting.

China Coltan Ore Mining Process Flow Chart for Beneficiation China

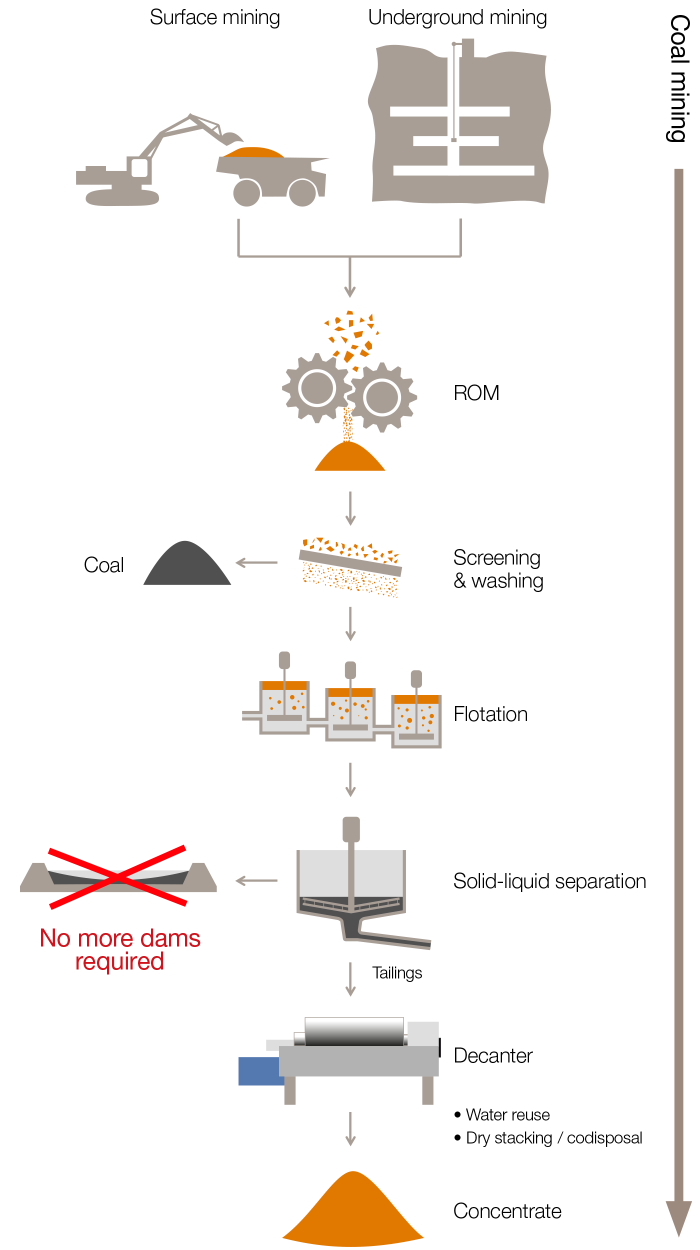

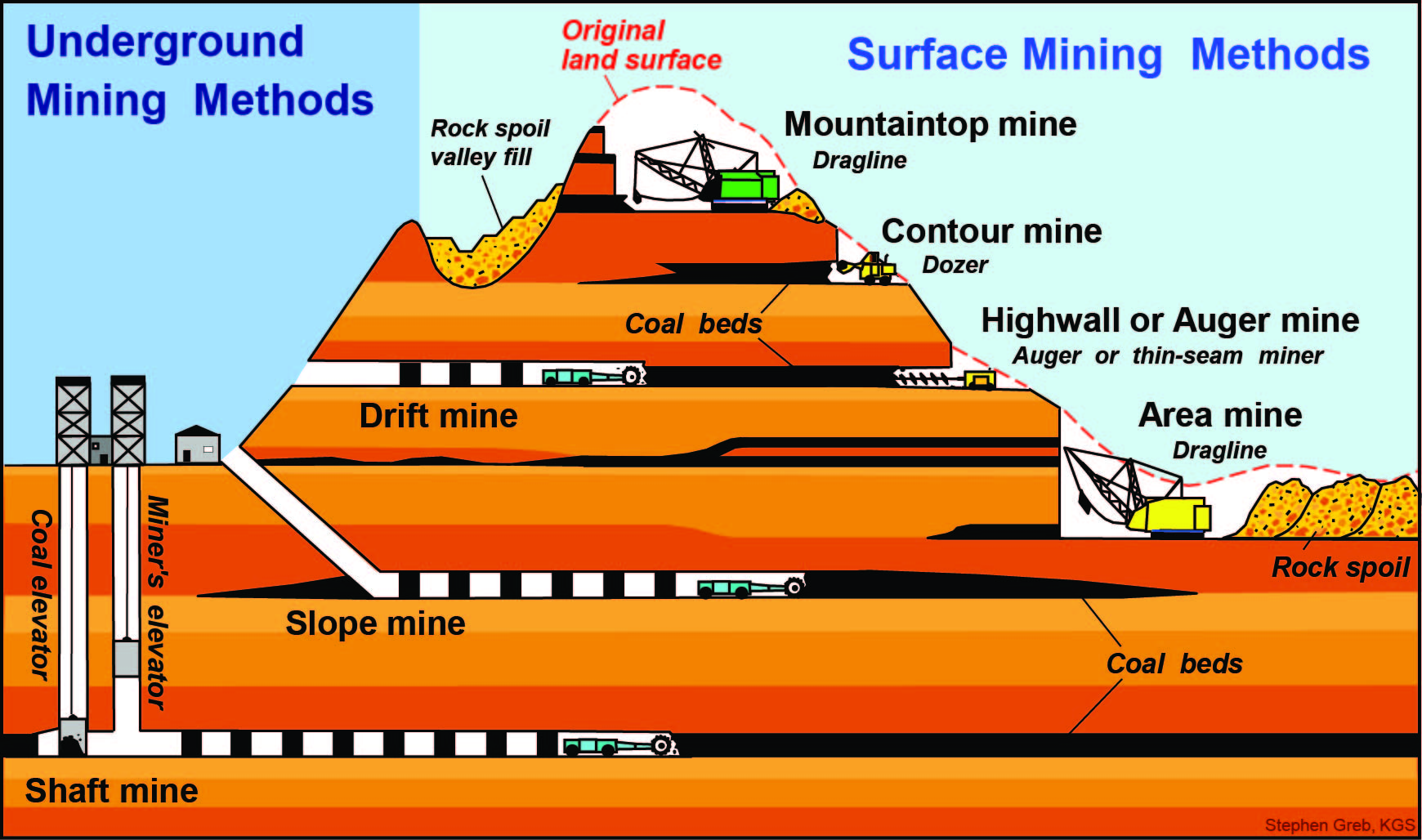

Coal mining - Underground, Surface, & Drilling: The various methods of mining a coal seam can be classified under two headings, surface mining and underground mining. Surface and underground coal mining are broad activities that incorporate numerous variations in equipment and methods, and the choice of which method to use in extracting a coal seam depends on many technological, economic, and.

Optimization and Simulation of Coal Mining Operations AnyLogic

A coal mine mantrip at Lackawanna Coal Mine in Scranton, Pennsylvania Coal miners exiting a winder cage at a mine near Richlands, Virginia in 1974 Surface coal mining in Wyoming, U.S. A coal mine in Frameries, Belgium. Coal mining is the process of extracting coal from the ground or from a mine. Coal is valued for its energy content and since the 1880s has been widely used to generate electricity.

Physics of Coal and Mining Process Mining Engineer's World

The technology of coal mining has gone through continual evolutions and several revolutionary changes which transformed the methods, equipment, and productivity over the decades. In recent years, advances in technology focused more on the use of communication systems, automation, and data sciences for the health and safety of the miners and.

Surface miners drive up savings in coal mining

Coal Mining. Feng et al. (2019) defined coal mining brownfield as the "land damaged, collapsed, occupied, or underutilized due to open-pit or underground mining, not only including abandoned mining operation systems, but also mining subsidence land and coal waste piles.". The process is made up of a coal mining operation, coal.

Process Flow Diagram Gold Mining, PNG, 700x523px, Process Flow Diagram

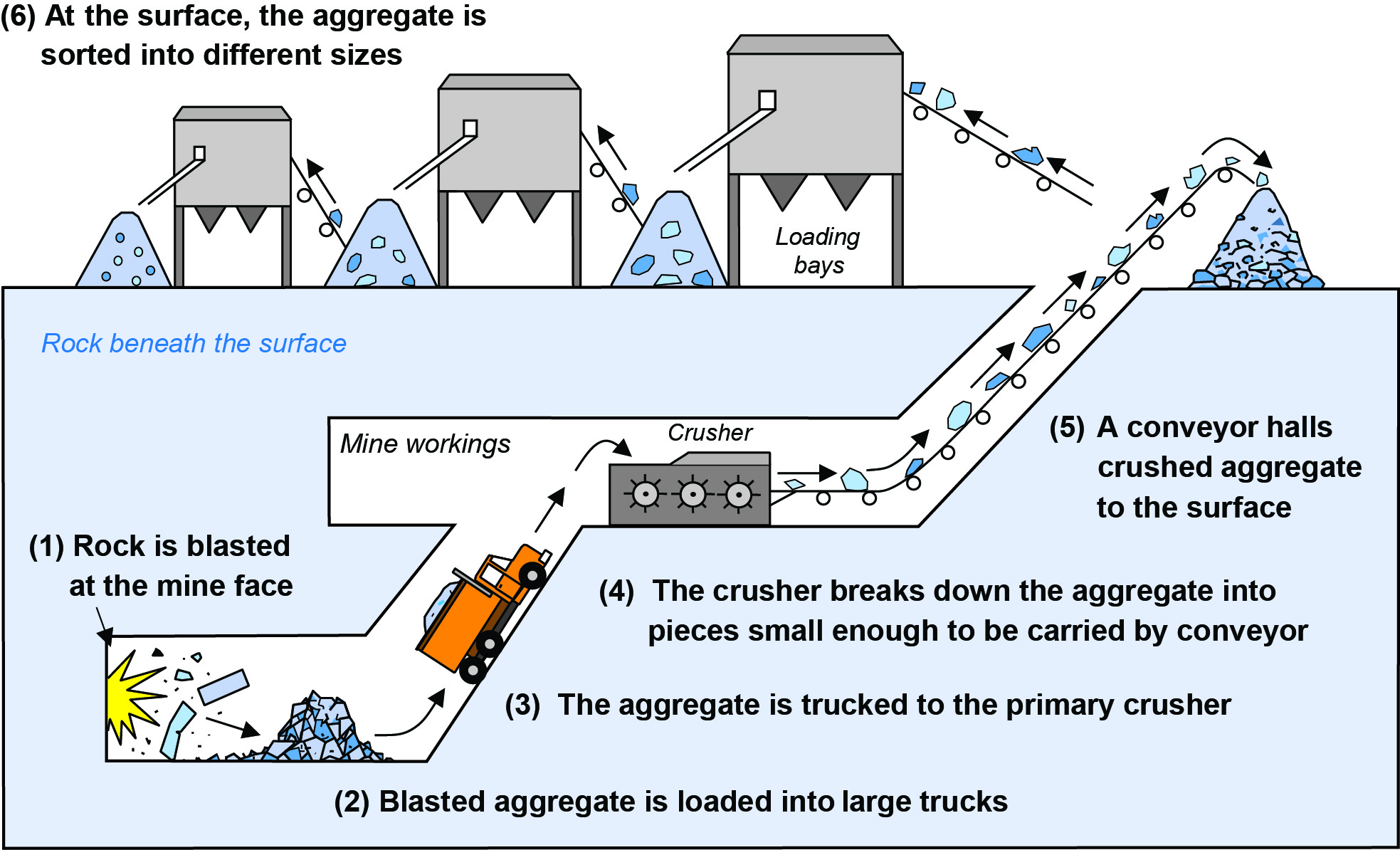

Underground mining, sometimes called deep mining, is a process that retrieves coal from deep below the Earth's surface—sometimes as far as 300 meters (1,000 feet). Miners travel by elevator down a mine shaft to reach the depths of the mine, and operate heavy machinery that extracts the coal and moves it above ground.

Most coal plants in the US contaminate groundwater with toxins report

In surface mining, the ground covering the coal seam (the overburden) is first removed to expose the coal seam for extraction. The elements of a surface mining operation are (1) topsoil removal and storage for later use, (2) drilling and blasting the strata overlying the coal seam, (3) loading and transporting this fragmented overburden material (called spoil), (4) drilling and blasting the.

Prasindo Consulting Coal is mined by two methods surface or

The U.S. Energy Information Administration estimates (as of October 2022) that in 2021, CO 2 emissions from burning coal for energy accounted for about 20% of total U.S. energy-related CO 2 emissions and for nearly 60% of total CO 2 emissions from the electric power sector. In the past, fly ash was released into the air through the smokestack.

Alfa Laval Coal Beneficiation

Pollution from Coal Mining. The process of coal excavation causes deterioration of the original morphological and pedological structure of the terrain and soil, and results in the release of harmful substances and/or mineral dust into the air. Such a release is primarily related to the deterioration of the upper seam structure during mining.

Industrial infographic illustrations Conveyors, Infographic

Mining coal. Coal miners use large machines to remove coal from the earth. Many U.S. coal deposits, called coal beds or seams, are near the earth's surface, but others are deep underground.Modern mining methods allow U.S. coal miners to easily reach most of the nation's coal reserves and to produce about three times more coal in one hour than in 1978.

Figure 1 from A new mining method Semantic Scholar

Two dominant methods account for the vast majority of underground coal mining: "room and pillar" and "longwall" mining.. In room and pillar mining, seams of coal are partially mined, leaving large pillars of coal intact to support the overlying layers of rock.When finished, miners practice "retreat" mining, extracting as much coal as possible from the remaining pillars as they.

Mine ExploitationCoal Mining Technology

Coal has a wide range of moisture (2-40%), sulfur (0.2-8%), and ash content (5-40%). These can affect the value of the coal as a fuel and cause environmental problems in its use. The depth, thickness, and configuration of the coal seams determine the mode of extraction. Shallow, flat coal deposits are mined by surface processes, which are.

Coal Flow Sheet

The aim of this Special Issue is to solicit original research articles and review papers reflecting the advances in research concerning process safety in coal mining. Topics include, but are not limited to: Coal mine disaster (outburst, rockburst, fire, water, and dust) prevention, control theory, and technology;

Coal Mining, Kentucky Geological Survey, University of Kentucky

Coal mining can be divided into two broad categories: surface mining and underground mining.. such as carbonization to produce coke for use in the steel-making process. Coal Composition. The composition of coal can be analyzed in two ways. The first is reported as a close analysis (moisture, volatile matter, fixed carbon and ash) or a final.

How govt plans to ease the process of coal mining Business

Coal mining - Coal preparation: As explained above, during the formation of coal and subsequent geologic activities, a coal seam may acquire mineral matter, veins of clay, bands of rock, and igneous intrusions. In addition, during the process of mining, a portion of the roof and floor material may be taken along with the coal seam in order to create adequate working height for the equipment.

Limestone Industry, Kentucky Geological Survey, University of Kentucky

Coal mining (also called colliery) is the process of extracting coal from the ground's surface or from deep underground. Coal miners literally raze entire mountain ranges to feed our insurmountable desire for cheap energy. There's something brutally simple about coal mining. Take away the monstrous-but-sophisticated machinery and eco.