Main parts of a singledisc clutch system Download Scientific Diagram

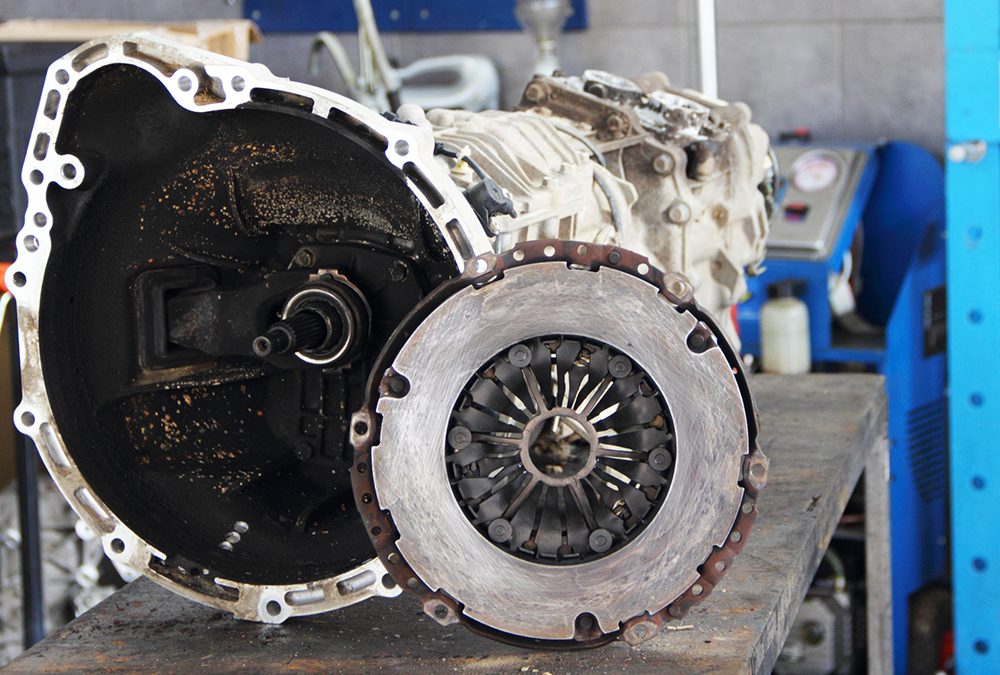

A friction clutch. Due to the amount of wear and tear caused by the friction between the clutch plate and the flywheel, certain machines use wet clutches. In a wet clutch, liquid lubricant helps the parts turn smoothly and stops them from wearing out as quickly from the constant friction. Dry clutches lack lubrication between parts.

What Is Single Plate Clutch Construction of Single Plate Clutch Working of Single Plate Clutch

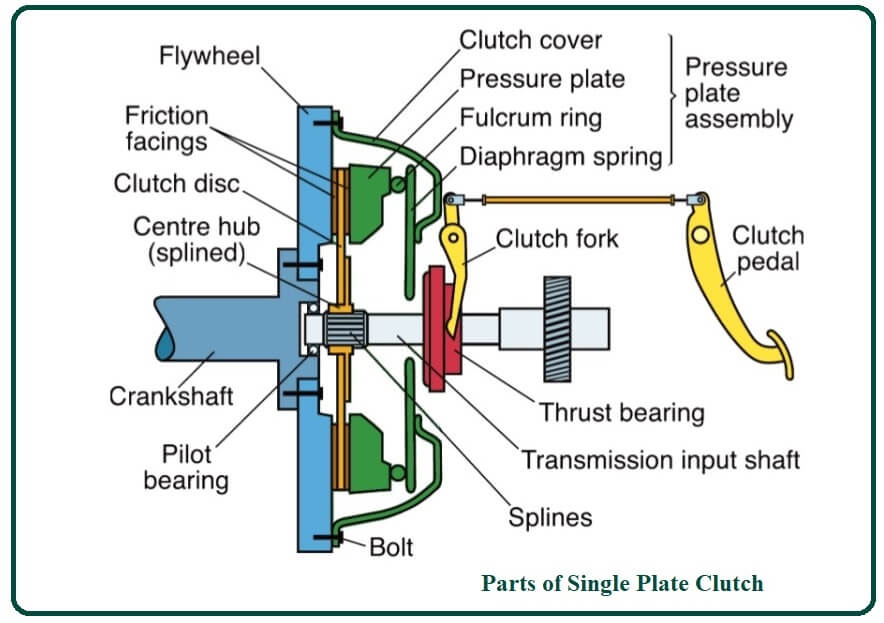

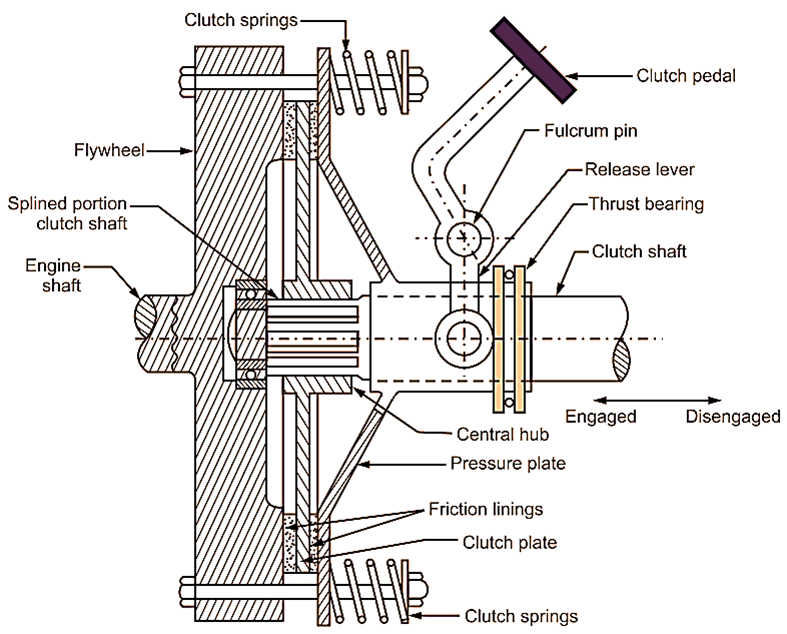

Single plate clutch diagram: Construction of Single plate clutch: 1) Single plate clutch consists of main three parts are friction plate, pressure plate, flywheel. And other parts are clutch pedal, clutch spring, and bearings.

Know How Selecting your clutch Repco Australia

1. Single plate clutch Engagement & disengagement of single plate clutch ! The single plate clutches have fewer parts comparatively & are very easy to understand. The device contains only 2 friction discs. Torque transmission takes place when both of them come in contact with each other.

Different Types of Clutches Explained in Detail [Notes & PDF]

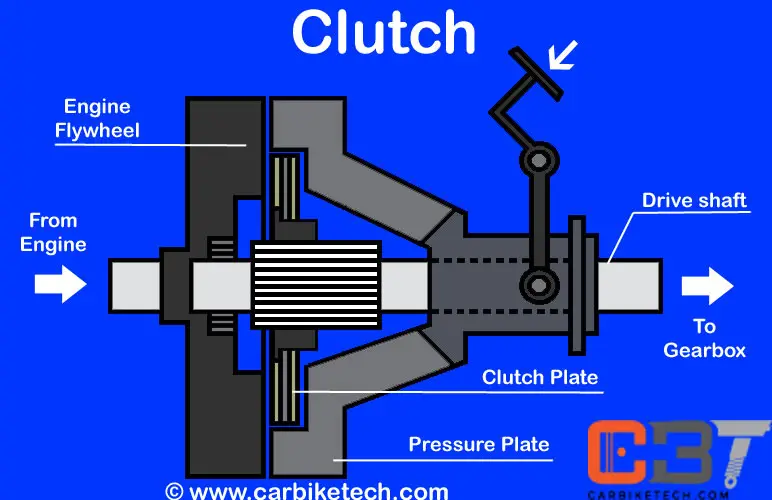

Clutch is a mechanical device used in the transmission system of a vehicle. It engages and disengages the transmission system from the engine. It is fixed between the engine and the transmission. When the clutch is engaged, the power is transmitted from the engine to the driving wheels through the transmission system and the vehicle starts moving.

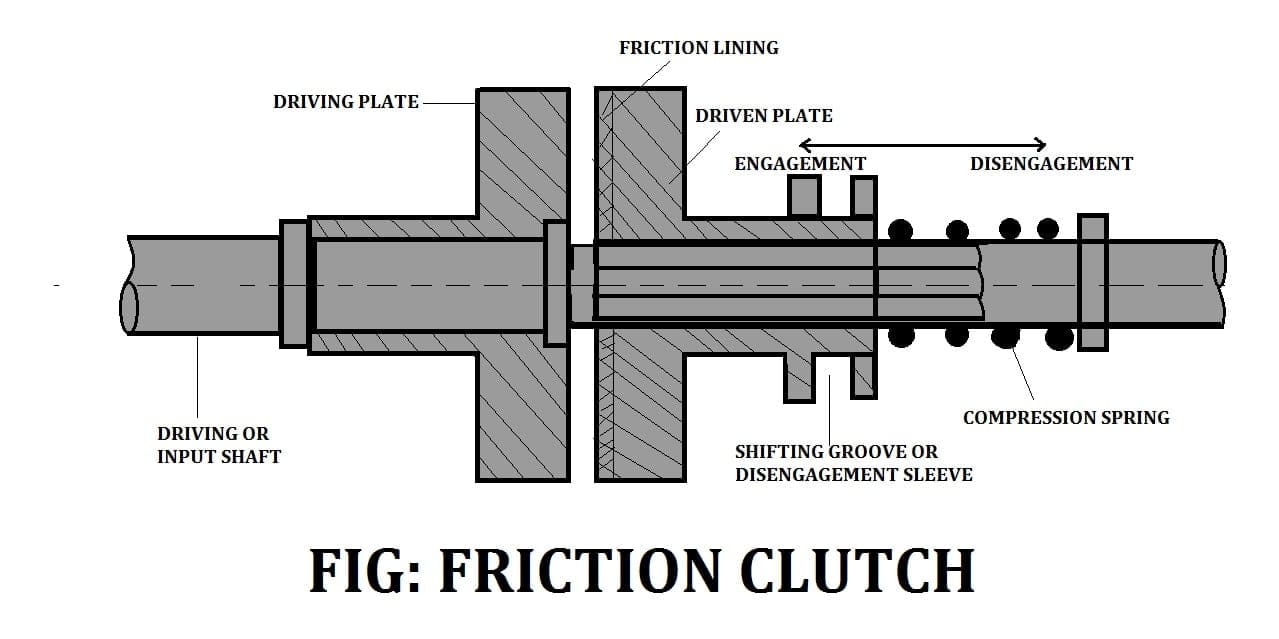

Friction Clutch ClipArt ETC

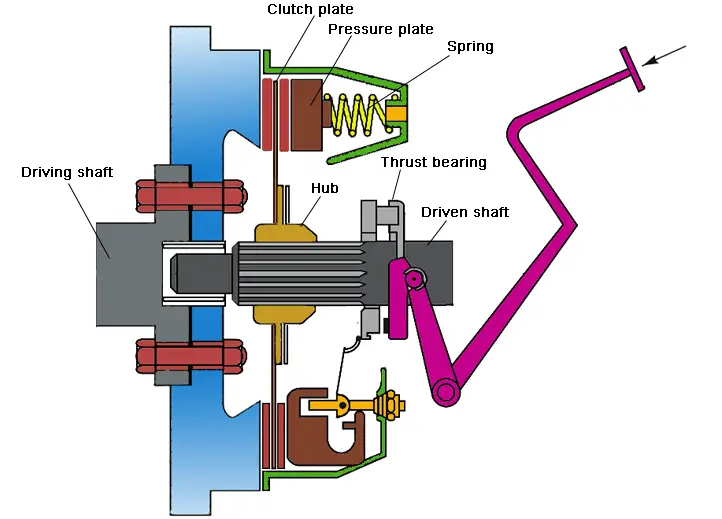

This diagram show the position of the clutch in a manual transmission, but clutches are found in both manual and automatic transmissions. Clutches are useful in devices that have two rotating shafts, including cars. One of the shafts is typically driven by a motor or pulley, and the other shaft drives another device.

10 Types of Clutch and How They Work? [Explained with Pictures] Engineering Learn

The driven (or friction) plate runs on a splined input shaft , through which the power is transmitted to the gearbox. The plate has friction linings, similar to brake linings, on both its faces. This allows the drive to be taken up smoothly when the clutch is engaged.

How does Friction clutch mechanism works YouTube

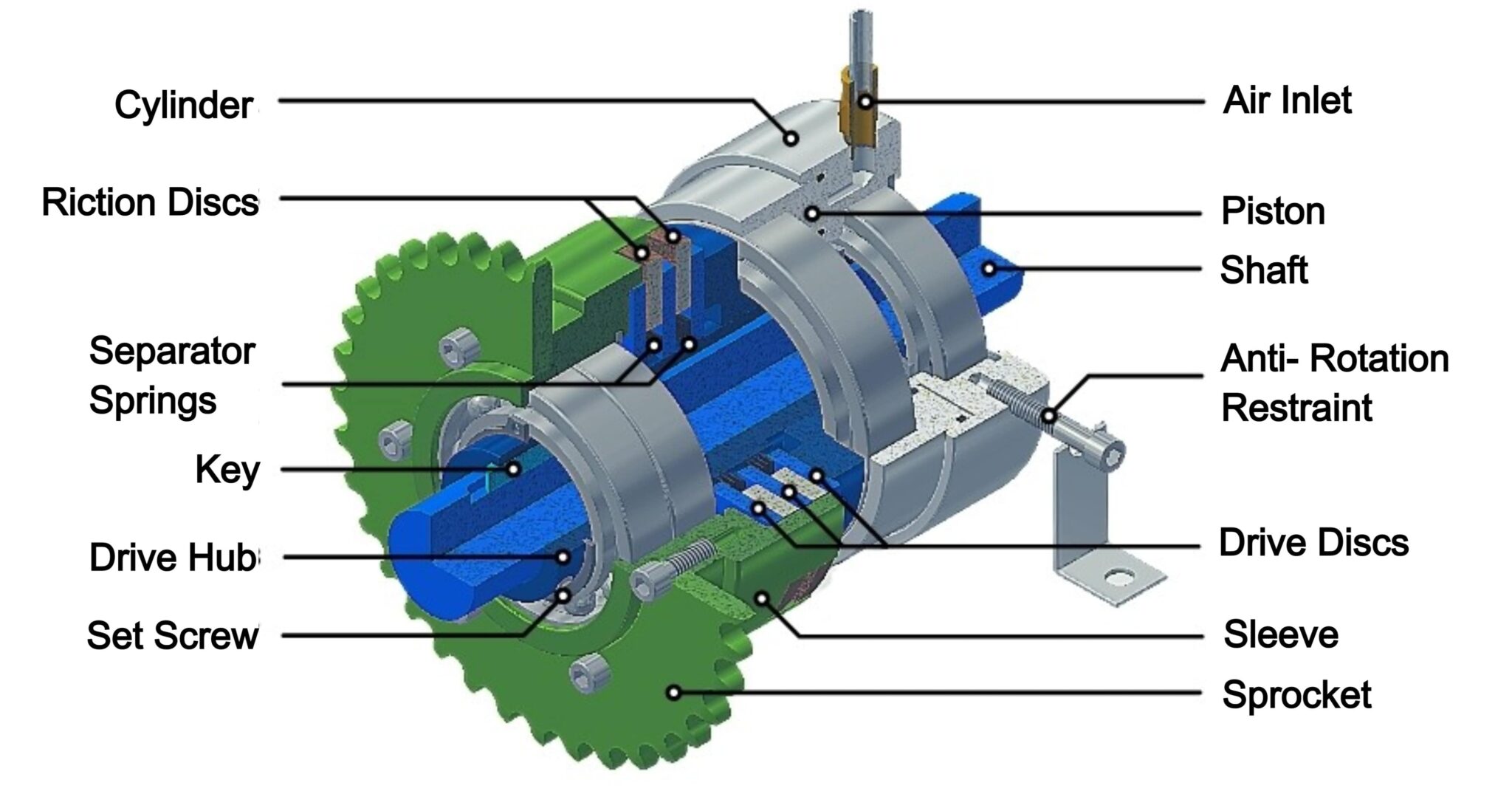

Friction clutches are mechanical devices used to engage and disengage the power transmission between an engine or motor and a driven component, such as a shaft or a machine. They operate on the principle of creating frictional contact between two surfaces to transmit torque and motion.

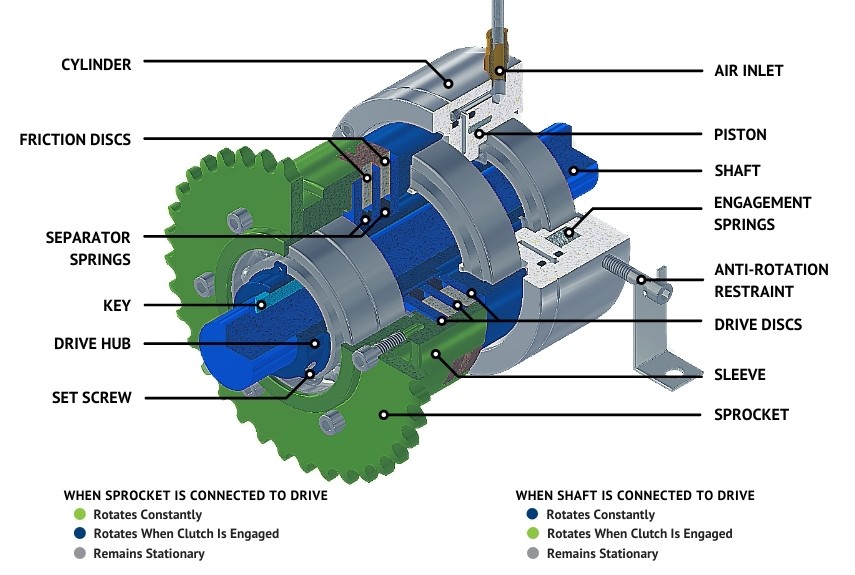

How It Works Spring Engaged Friction Clutch Mach III

19K Share 1.7M views 5 years ago physics and animation video Cars of today normally use a car clutch to transmit power produced by the engine to the gear box. The vast majority of cars and.

(a) 3D model of the friction clutch assembly (single plate). (b)... Download Scientific Diagram

A friction clutch is a type of clutch that uses friction to connect and disconnect the power transmission from the engine to the transmission. It typically consists of a flywheel attached to the engine, a pressure plate, and a clutch plate.

How a Single Plate Clutch Works? Mech4study

The below figure shows the diagram of a hydraulic clutch system used in an automobile. It consists of the following parts. 1) Flywheel: The flywheel is connected to the engine crankshaft.

What is Single Plate Clutch? Working, Diagram, Construction & Applications ElectricalWorkbook

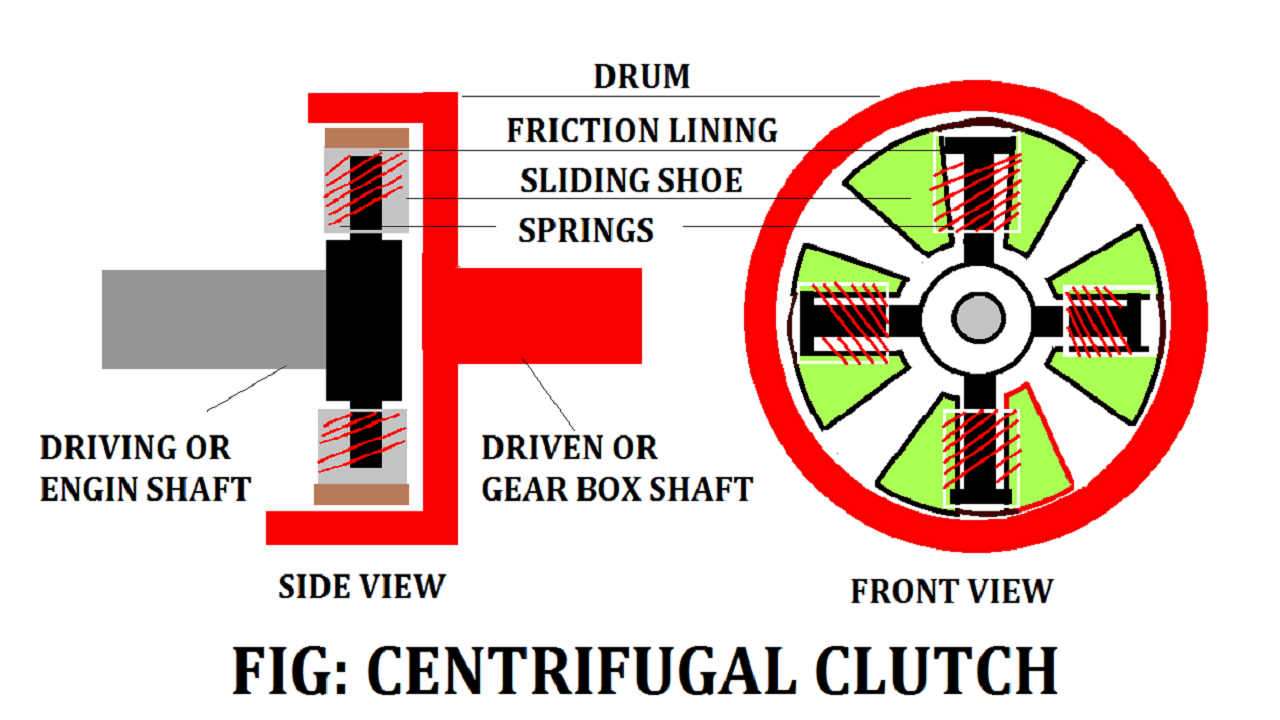

Working of Centrifugal clutch: Engagement: -. When the vehicle engine starts, the driving element starts rotating with a crankshaft. When the driving element starts rotating, the shoes expand radially due to centrifugal force. When the driving element achieved preset speed, the friction starts between the shoes & driven element.

Understanding How a Friction Clutch Plate Works Technician.Academy

#2. Friction Clutches: The friction clutch is another most important type. It is used to transmit the rotary motion of one shaft to another when desired. The axes of the two shafts are coincident. The surfaces can be pressed firmly against one against when engaged and the clutch tends to rotate as a single unit.

Different Types of Clutches Explained in Detail [Notes & PDF]

Construction: Cone clutch working: Cone clutch advantages: Cone clutch disadvantages: Application of cone clutch: Cone clutch diagram: Working principle: Cone clutch works on the Principle of friction. The outer cone has a friction lining on its inner conical surface & Inner cone has friction lining on its outer conical surface.

Clutch Technology Part Two, The Clutch Disc Friction Material MotoIQ

4] Friction disc:- It is also known as friction plate. It has asbestos lining for frictional contact. The friction plates are externally toothed and these plates are mounted into the clutch drum. The friction plates can easily slide into the slots of clutch drum. 5] Steel plate:- These plates are internally toothed and mounted on inner splined hub.

Friction Materials What Are They? How Do They Work? Types

Friction clutch Single plate clutch Multiplate clutch Wet Dry Cone clutch External Internal Centrifugal Clutch Semi-centrifugal clutch Conical spring clutch or Diaphragm clutch Tapered finger type Crown spring type Positive clutch Dog clutch Spline Clutch Hydraulic clutch Electromagnetic clutch Vacuum clutch Overrunning clutch or freewheel unit

Automotive Clutch Characteristics & Types CarBikeTech

A friction clutch transmits power by virtue of friction developed between contacting surface. The friction surface is typically flat and perpendicular to the axis of rotation. Two or more surface is pressed together by using compression spring.