12K, 2 x 2 Twill Weave Carbon Fiber Fabric, 5.7oz/sq yd Fibre Glast

A 2 x 2 twill will be balanced, as each warp yarn goes over two weft yarns and then under two weft yarns. Adding 2 plus 2 to get 4 means the weave repeat is on 4 warp yarns and 4 weft yarns. Therefore, this weave design requires at least 4 harnesses or some multiple of 4 to accommodate more warp ends.

2 x 2 twill weave carbon fabric woven from standard modulus 12k carbon fiber

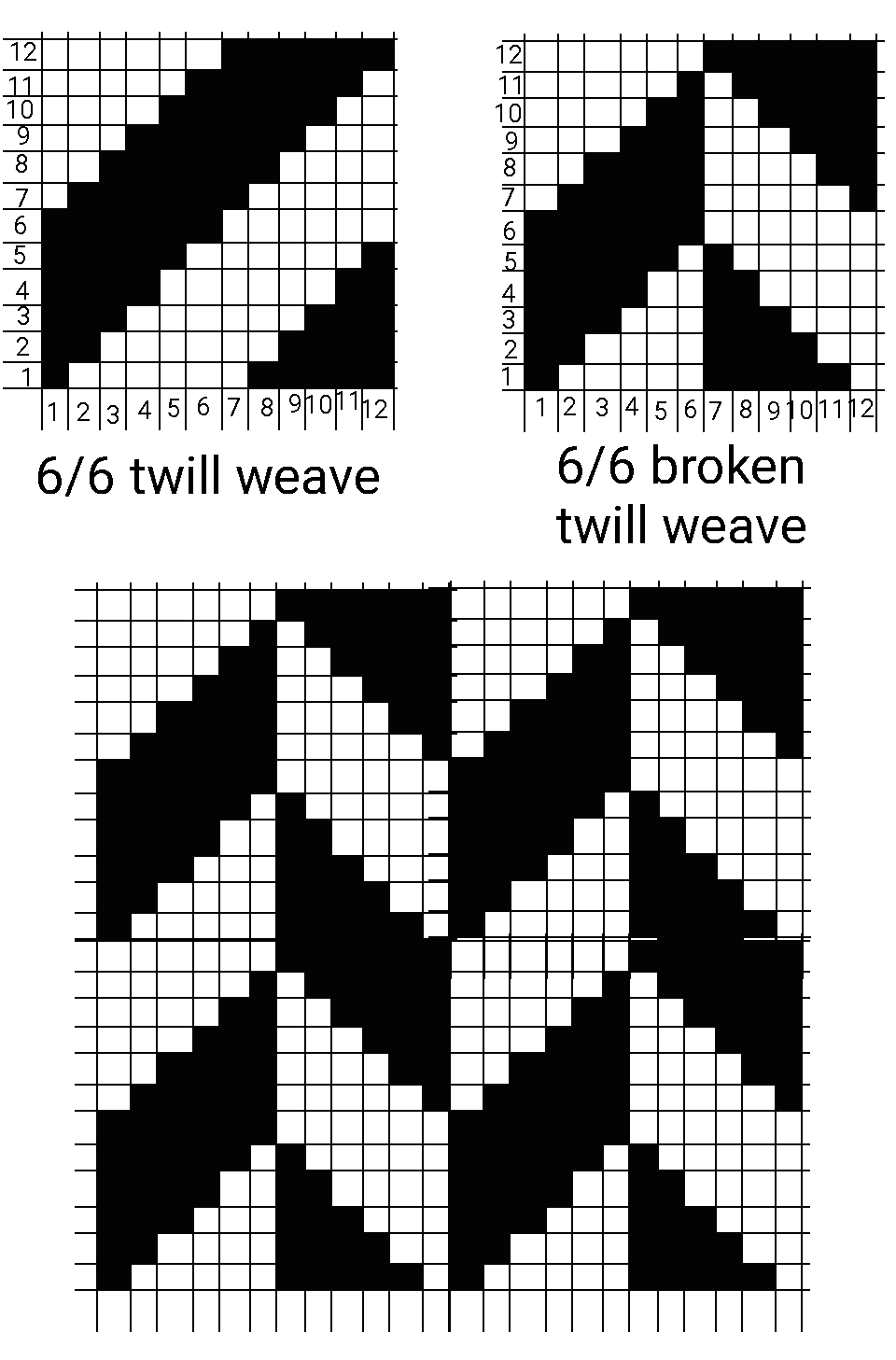

Combination twill weaving. Combination twills find extensive use in the worsted industry in the production of garment fabrics, as these weaves are capable of producing compact textures. These twills are constructed by two methods 1. End and end combination 2.Pick and pick combination. In the first method the twill weaves are combined end way.

Basic Weave Structures Twill Gist Yarn

1/3 Twill and 2/2 Twill The two most basic twills are 1/3 or 3/1, and 2/2. These abbreviations suggest how many ends your weft is skipping over or under. In the image below, you can see an example of a straight twill threading. On the left is the 1/3 twill, and on the right, you can see a 2/2 twill.

Plain, Twill, and Satin Weave the Three Basic Weaves! Charu Creation

2×2 Twill is likely the most recognizable carbon fiber weave in the industry. It is used in many cosmetic and decorative applications, but also has great functionality, it has both moderate formability and moderate stability. As the 2×2 name implies, each tow will pass over 2 tows then under two tows.

2 x 2 twill weave carbon fabric woven from standard modulus 12k carbon fiber

2×1 A lightweight 2×1 denim from Pacific Blue As you may have guessed, 2×1 is just two warp threads for every weft thread. We've covered summer weight denim options at Heddels before, which typically clock in at less than 10.5 Oz. These pairs of denim are likely woven using a 2×1 weave.

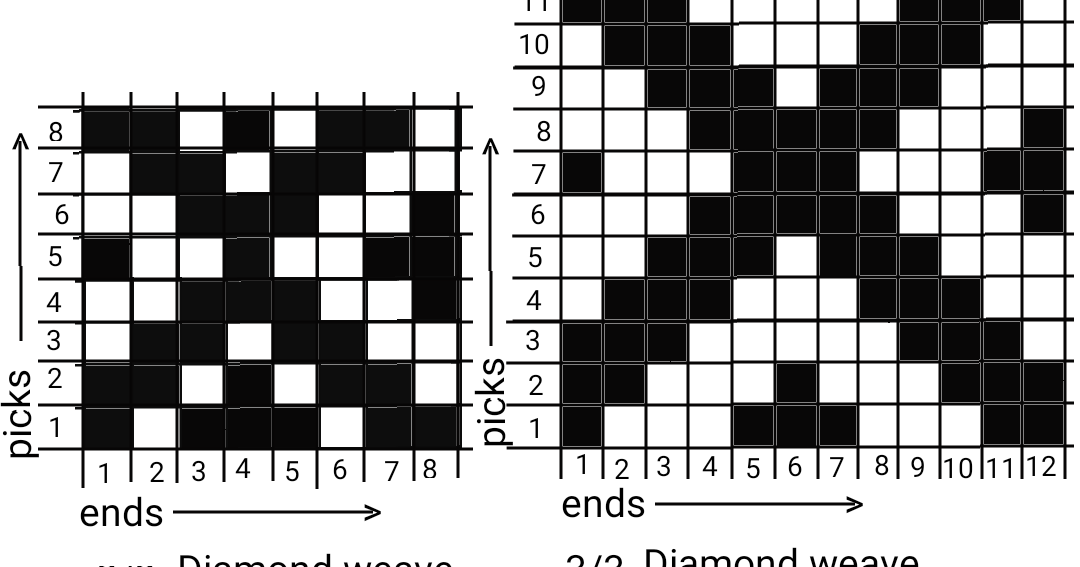

diamond herringbone weaving draft Google Search Weaving, Weaving patterns, Loom weaving

Twill Weave Satin/Sateen Honeycomb Weave Huck a Back Weave Crepe Weave Bedford Cord Weave Welts and Pique Mock Leno Weave All types of basic weave structure are described briefly. Plain Weave: In a plain weave, each warp yarn passes over alternate weft yarns. Neighbouring warp yarns pass over the adjacent weft yarns.

Textile Adviser Broken twill weave

A twill weave is characterized by diagonal lines of warp and weft floats on the face of the fabric. Twill line may be from lower lift to upper right (Z-twill) or from lower right to upper lift (S-twill) corner. Smaller repeat twill is (3). It means take at least end and three picks produce twill weave.

Prepreg 3K, 2x2 Twill Weave Carbon, stock same day ship Fibre Glast

Weave: 2×2 Twill Carbon Fiber Tow Size: 6K Thickness: .017″ This 6K version of the 2×2 twill allows for fast buildup but still has good conformability. Used mainly as a structural reinforcement cloth, but is sometimes used for cosmetic applications where a larger weave pattern is desired. (will not contour as easily as the 5.7oz 2×2 Twill.

What is Twill? Bourne Crisp Melbourne Australia

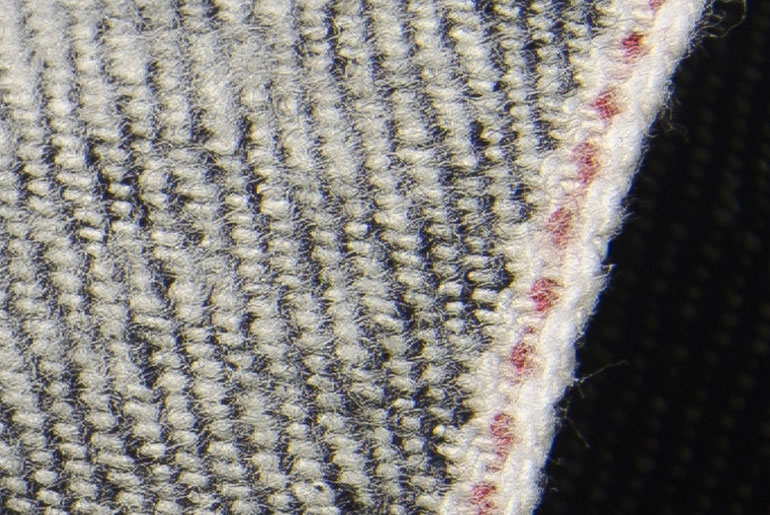

Twill fabric is any fabric made with a special twill weaving technique that results in diagonal ridges in the fabric. It is not specific to any particular fiber and can be made from cotton, linen, silk, or man-made fibers.

Textile Adviser Broken twill weave

1. Durable. Twill fabric is very durable and can withstand a lot of wear, making it a great fabric for clothing and upholstery. 2. Opaque. The twill weave does not create a sheer quality, so all twill fabrics have great opacity, making them great for curtains, housewares, and clothing. 3.

How to Weave 2/2 Twill on Cardboard Loom YouTube

Description This fabric has a tow size of 12k and is woven in a 2×2 twill weave. This is the most widely used weave pattern across multiple industries. This material is woven tighter than most of our competitors' fabrics. This will help ensure a straight weave and a better looking final product. Available in 24″, 50″ & 60″ widths

3k 2x2 Twill Carbon Fiber Fabric High Modulus Carbon Fiber Weave Roll

2×2 Twill Weave Pattern. To understand the x2 twill weave pattern, begin by examining its unique characteristics and applications. This weave pattern is known for its distinct diagonal lines and is commonly used in high-performance applications due to its exceptional strength and flexibility.

Twill Weave Structure, Properties, Uses & Types TREASURIE

A 2/2 twill means you weave over and under two warp yarns at a time. This is like HOPSACK WEAVE except you start each row one along from the previous row. You can use one, two or more yarns together in your weft, like in any weave. To learn more, watch this 5-minute film or look at the short instruction sheet.

Textile Adviser DIAMOND WEAVE ( A DERIVATIVE OF TWILL WEAVE)

An overview of twill weave, a common weaving technique used in textile production, and the characteristics, properties, and various types of fabrics that are created using the twill weave. Updated on: October 18, 2023 By Sarina Tariq Twill weave- Denim fabric

Know Your Twills 3x1, 2x1, and Plain Weave

Twill weave is second basic weave from the production and using point it view, it is also in second position .Mainly the fabric painting are made it the structure.Example: Denim fabric (3/1) made.

Twill Weave Structure, Properties, Uses & Types TREASURIE

What is a 2/2 twill weave? A 2/2 twill is a balanced weave, meaning that the pattern uses the same amount of warp strings (2) and weft yarns (2) to produce a diagonal striped appearance. The stripe is built by staggering one warp thread in each row of the weaving, and continuously weaving all four rows of the pattern repeat.