Example of bathtub curve as given by Eq. 3 (showing 3 stages) Download Scientific Diagram

Bathtub Curve: Pengertian, Makna, dan Pembahasannya! Berikut ini adalah postingan artikel kategori Istilah Teknologi Lainnya yang membahas tentang penjelasan pengertian, definisi, dan arti dari istilah kata bathtub curve berdasarkan rangkuman dari berbagai jenis macam sumber (referensi) relevan, terkait, serta terpercaya.

(DOC) Bathtub Curve Kak Sam Academia.edu

Berikut ini adalah postingan artikel kamus teknis bidang teknik teknologi Keinsinyuran yang menjelaskan tentang pembahasan pengertian, definisi, dan arti dari istilah kata bathtub curve berdasarkan dari berbagai jenis macam sumber (referensi) relevan, terkait, serta terpercaya yang sudah Kami rangkum dan kumpulkan.

The bathtub curve and the lifetime of an asset Sensorise

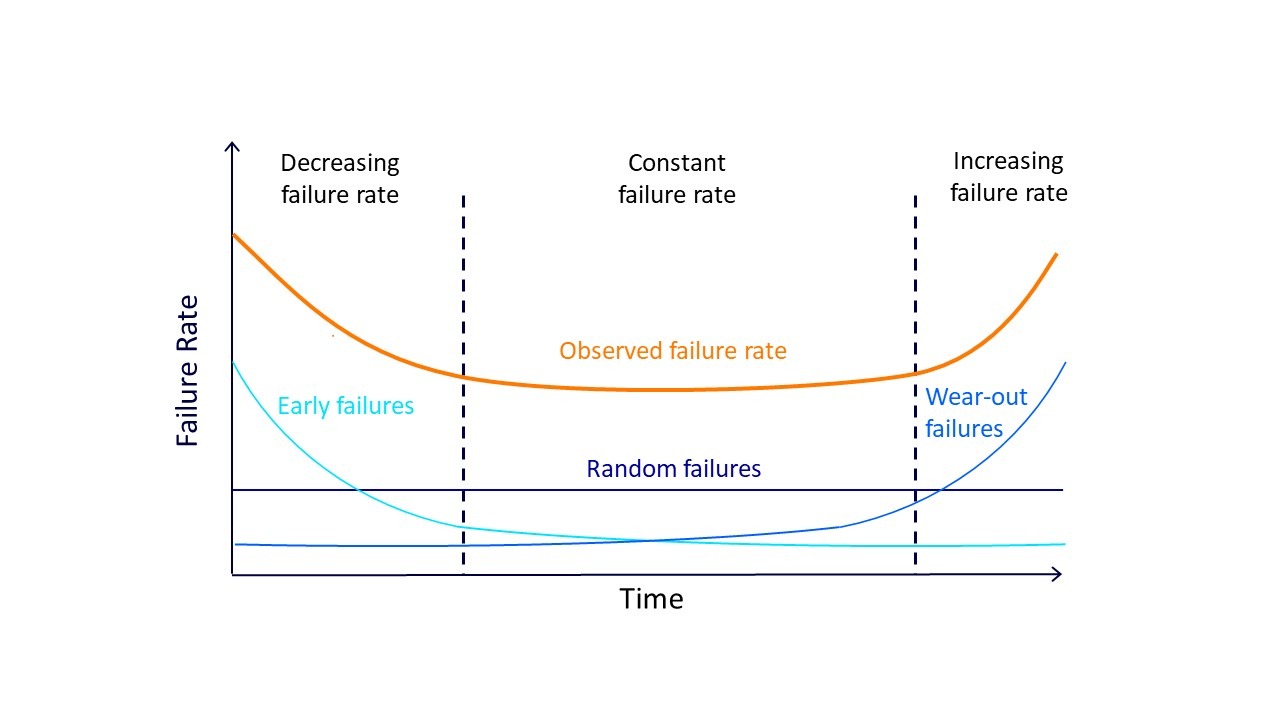

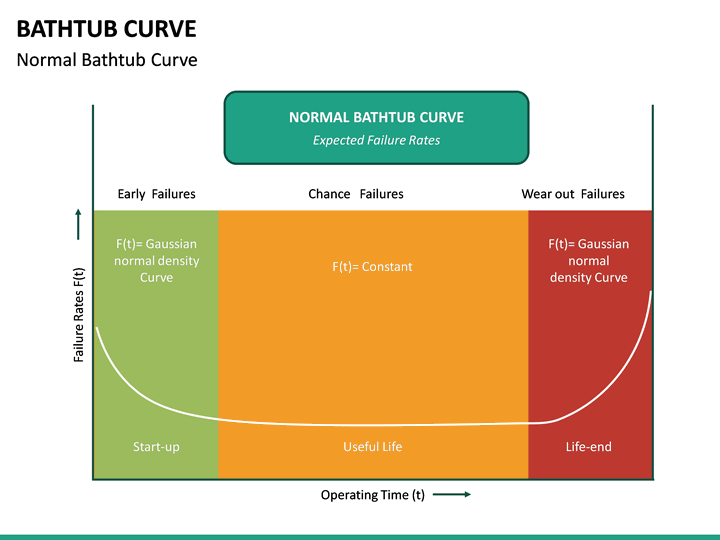

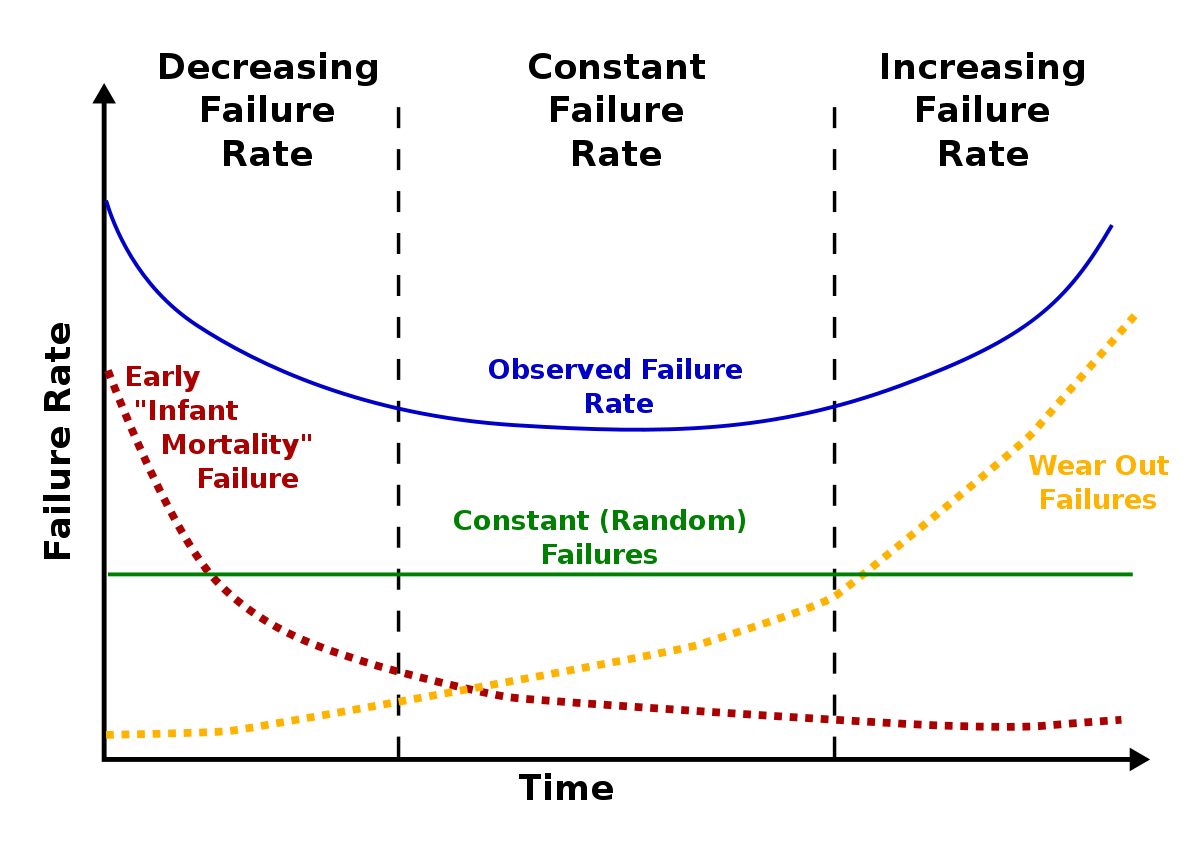

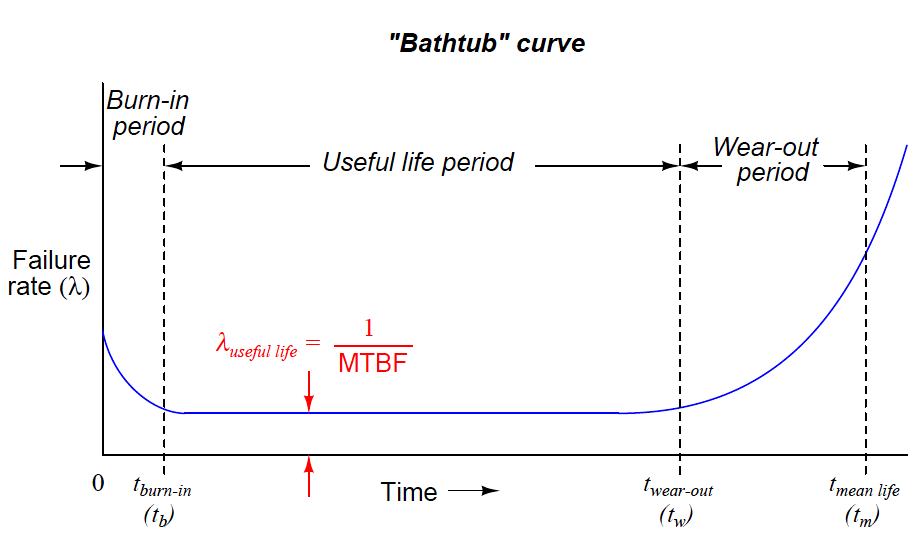

Because of the shape of this failure rate curve, it has become widely known as the "Bathtub" curve. The initial region that begins at time zero when a customer first begins to use the product is characterized by a high but rapidly decreasing failure rate. This region is known as the Early Failure Period (also referred to as Infant Mortality.

The Bathtub Curve in Reliability Quality Gurus

Sesuai namanya Bathtub Curve adalah Kurva bak mandi. Karena bentuk kurvanya mirip bak mandi. Diawali oleh garis melengkung ke bawah. dilanjutkan garis mendatar. dan diakhiri dengan garis melengkung ke atas jadi mirip sama bak mandi atau bathtub. Sumbu Y dari kurva itu adalah "tingkat kegagalan" sedangkan sumbu X nya adalah "waktu".

Bathtub Curve PowerPoint Template SketchBubble

The curve "bathtub", as it's known, presented in Figure 1 is frequently used to describe the failure rate λ (t) of equipment [9]. It illustrates three stages in a product's life cycle and.

Bathtub Curve Sensor and Transducer YouTube

Figure 1. Bathtub curve (a schematic). λ(t) - failure rate; t - time.I - stage of early failures; II - steady state, useful life, III - wear-out period. Stage I. Failure rate λ(t) is high at the beginning and decreases with time.The failures occur due to errors in design, weak components or inferior materials, due to faults appearing during manufacture or building, or due to.

Bathtub Curve In Maintenance Of Equipment Reliability Solutions The hits can be great, but

Bathtub curve (a schematic). λ(t) - failure rate; t - time. I - stage of early failures; II - steady state, useful life, III - wear-out period. hidden defects, and mistakes of the personnel. (In the case of people, the reasons for the "failures" during this stage are traffic accidents, diseases, wars, and murders.)

25 Illustration of the bathtub curve relationship [From Barry W.... Download Scientific Diagram

The bathtub curve is a fundamental concept in maintenance and reliability engineering. Imagine the shape of a bathtub - it starts with a steep slope, flattens out in the middle, and then ends with another steep slope. This curve describes how the failure rate of many products and systems changes over time. In the early life of an asset.

3 The " bathtub curve " Download Scientific Diagram

Since the bathtub curve helps us determine the asset's expected useful life and reliability, it's easier to keep it under control. But the main advantage is undoubtedly being able to more accurately plan how and when to perform maintenance. The ultimate goal, as always for facility managers, is to extend the asset's useful life and.

The BathTub Curve YouTube

Bathtub curve The reciprocal value of the MTBF that is a measure for the reliability of a component is the failure rate λ. Plotting of the statistical failure rate λ over time t gives the bathtub function shown below (bathtub curve). Failure rate Failure rates have the dimension of 1/time unit. The term FIT (failures in time) is

Illustrative Bathtub Curve with New Innovations Download Scientific Diagram

The 'bathtub' refers to the shape of a line that curves up at both ends, similar in shape to a bathtub. The bathtub curve has 3 regions: The first region has a decreasing failure rate due to early failures. The middle region is a constant failure rate due to random failures. The last region is an increasing failure rate due to wear-out failures.

Bathtub Curve How to Measure Asset Realiability (with formulas)

The bathtub curve is described in nearly every standard reliability text, e.g., [2], [3], [7], [13], [15]-[19]. The curve represents the idea that the operation of a population of devices can be.

Bathtub Curve Reliability and How Repairs Affect It Global Electronic Services

The basics of Reliability for those folks preparing for the CQE Exam1:15- Intro to Reliability1:22 - Reliability Definition2:00 - Reliability Indices06:48 -.

The Bathtub Curve ENGN2226 Online Classroom YouTube

The bathtub hazard rate curve shown in Figure 12-1 is often used to describe failure behavior of many engineering items. Its name comes from the hazard rate's resemblance to the shape of a bathtub. For the purpose of performing various reliability studies, the bathtub hazard rate curve is divided into three regions: decreasing hazard rate region, constant hazard rate region, and increasing.

Bathtub Curve Safety Instrumented Systems Instrumentation Tools

Time to look at an example of MTBF. Imagine, one of your assets runs for 24 hours every day and has an MTBF of 3.5 million hours. Below is the failure rate calculation when the bathtub curve has a flat bottom. MTBF = 1/failure rate. Failure rate = 1/MTBF = 1/3,500,000 hours. Failure rate = 0.000000286 failures/hour.

Classical Bathtub Curve Download Scientific Diagram

In reliability context, the so called bathtub curve is an idealized representation of the failure rate (or MTBF) of a population of items over time. The bathtub curve has three phases, each of them representing a product life phase. Lambda = failure rate = 1/MTBF, and t = time. are typical for immature products with design flaws.